TechnoAlpin - Research Leads To Unique Sophistication & Greater Efficiency

echnoAlpin has always put a lot of effort into research and development to make snow guns even more efficient and user-friendly. In recent years, several decisive steps have been taken that underpin TechnoAlpin's technological pioneering position.

One of them is the new nozzle valve technology. The nozzle blocks on the new valve ring can be controlled individually, unlike the previous model, where certain combinations were specified. The optimal combination is now always guaranteed and the snow gun is even more powerful overall and always works at optimal efficiency.

In addition, the water in the nozzle valves is no longer emptied downwards during operation, but is integrated into the air jet at the front. So not a drop of water is wasted. The heated drain hose is saved as a result.

The new TechnoAlpin models only need one motor for the turbine and compressor. The additional electric motor for the compressor is no longer required. This reduces the maintenance effort and the snow guns are quieter overall.

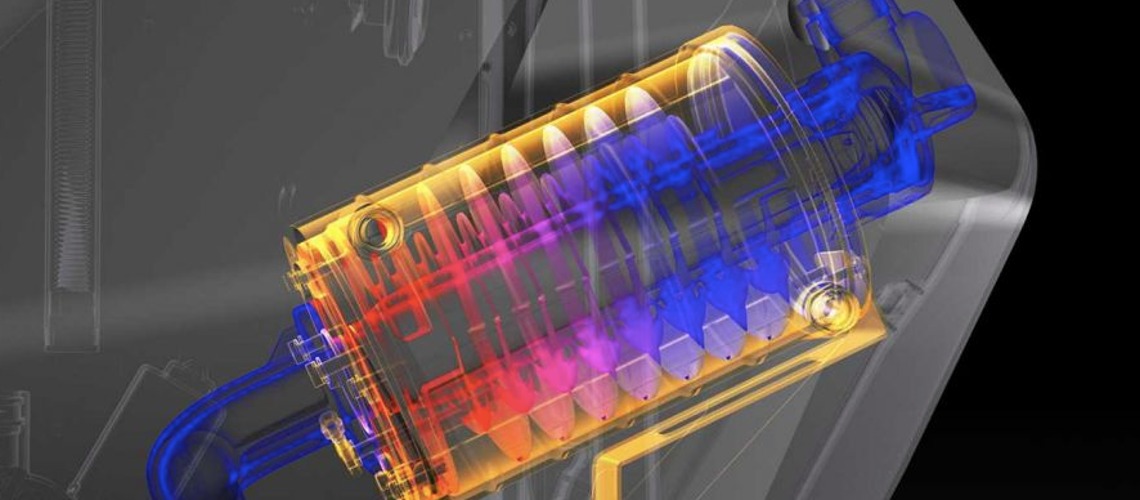

The air temperature is decisive for a high snow output in the border area. The new snow guns therefore have a heat exchanger with a very large cooling surface. The compressed air is routed around the cold snow water and cooled from approx. 100°C to 10°C - without any additional energy consumption. By using the waste heat from the compressed air, additional heaters in the water filter can be dispensed with and thus around 30% of the heating capacity can be saved.

The correct snowmaking position of the snow guns is central to high efficiency. The new snow guns have a mechanical concept that automatically puts the snow gun in the snow-making position when it is started up. After the snow has finished, the snow guns automatically go into the standby position to prevent damage.

In order to use as many resources as possible in procurement and logistics, an attempt was also made to standardize the new models as far as possible. The snow guns of the TT and TR families consist of 90% identical parts.

All components are based on being as durable and robust as possible. This is also reflected in the nozzles and nucleators, which have a ruby insert. Ruby is many times harder than stainless steel and is hardly ground down, even in aggressive water. The snow quality remains consistently high over the years and material wear is significantly reduced.

All in all, all these clever solutions mean that the new models produce around 15% more snow than their predecessors - with the same energy consumption. In addition, there is less wearing material and the maintenance effort is lower than ever. This conserves further resources and increases occupational safety.